Dabu printing is a traditional textile printing technique that originated in Rajasthan, India, several centuries ago. The word ‘dabu’ means mud in Hindi, and the technique involves using a mixture of mud and other natural materials to create intricate patterns on textiles.

History of Dabu Printing

History of Dabu Printing

The history of Dabu printing can be traced back to the 8th century, during the reign of the Chippa community of Rajasthan. The Chippa community was known for their expertise in block printing, and they used the Dabu technique to create beautiful and intricate designs on fabrics.

Over time, the Dabu printing technique spread to other parts of Rajasthan, including Jaipur, Jodhpur, and Udaipur, where it gained popularity among the local communities. The process was passed down from generation to generation, and many families still practice this traditional art form to this day.

Dabu printing was initially used to create traditional Rajasthani garments, such as sarees, lehengas, and dupattas. However, over time, the technique was adapted to create modern designs and patterns that cater to a broader audience.

Despite the emergence of new printing techniques, Dabu printing remains a significant part of Indian textile heritage. The craft is celebrated for its use of natural materials, sustainable practices, and the intricate designs it produces. Today, Dabu printing is widely used in the fashion industry, home decor, and accessories, and it continues to evolve as designers experiment with new colors, patterns, and materials.

Process of Dabu Printing

Step 1: Preparing the Fabric

The first step in the Dabu printing process is preparing the fabric. The fabric is washed and soaked in a solution of water and alum to make it absorbent. Then, it is dried and stretched on a printing table.

Step 2: Making the Dabu Mud

The next step is to make the Dabu mud. Dabu mud is a special mixture made from clay, wheat flour, and natural gum. The mixture is kneaded until it becomes smooth and free of lumps. It is then left to rest for a few hours to mature.

Step 3: Applying the Dabu Mud

After the mud has matured, it is applied to the fabric using wooden blocks. The blocks are dipped into the mud and then pressed onto the fabric in a repeating pattern. The mud will act as a resist, preventing the dye from penetrating the fabric.

Step 4: Applying Natural Dye

Once the mud has dried, the fabric is ready for dyeing. Natural dyes are used in the Dabu printing process. The fabric is dipped into the dye bath, and the dye penetrates the areas that are not covered by the mud. The fabric is then left to dry.

Step 5: Washing and Drying

After the fabric has dried, it is washed to remove any excess mud or dye. The fabric is then dried in the sun.

Step 6: Repeating the Process

To create multi-colored patterns, the process is repeated with different mud and dye combinations.

Dabu printing is a labor-intensive and time-consuming process that requires skilled craftsmen. The unique combination of resist dyeing and mud printing results in beautiful, intricate patterns that are popular in clothing, home furnishings, and other decorative items. Despite the modernization of printing techniques, Dabu printing remains an important part of Indian textile heritage.

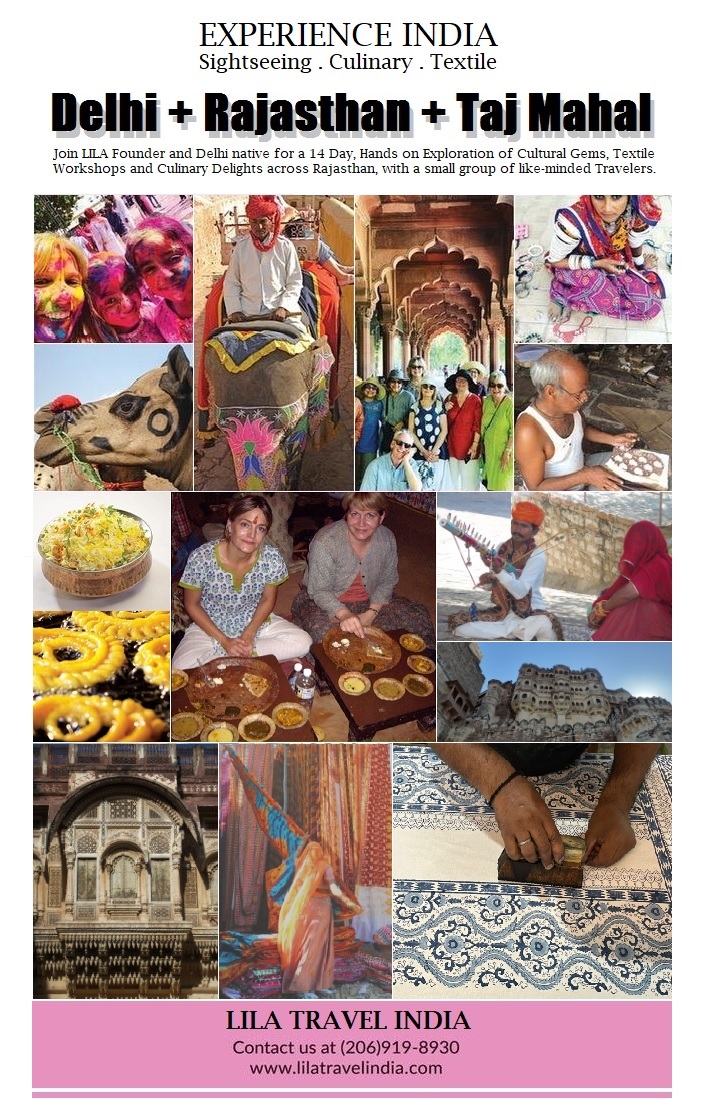

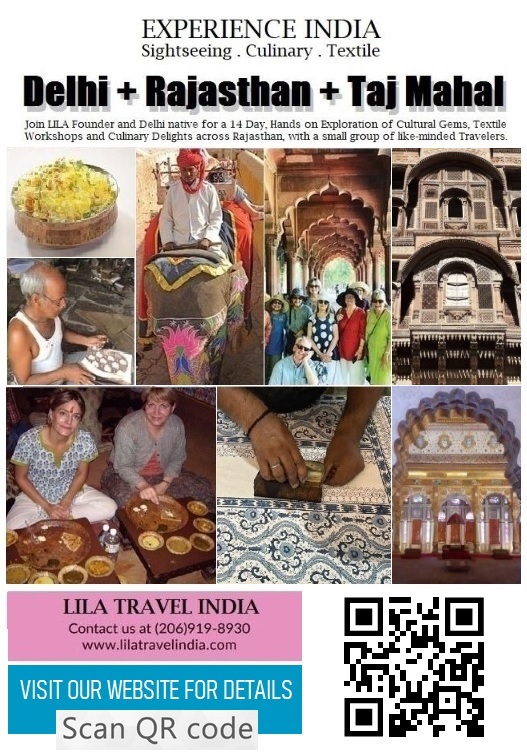

Want to learn more? Join Lila Travel India’s Textile Tour of Rajasthan to get a rich insight into the traditional art of Block Printing.

Culture Culinary Craft Tour of Rajasthan India – Experience India’s textile heritage on immersive tours by Lila Travel India – Led by Delhi Native based in Seattle USA – https://lilatravelindia.com/culture-culinary-textile-tour-of-rajasthan/

#culturaltourrajasthan #culinarytourindia #textiletourindia #luxurytoursindia #rajasthan #india #lilatravelindia